JGX-0320D-20A Wire Rope Vibration Isolator For Precise Shock And Vibration Control

Product Specifications

| Attribute |

Value |

| Material |

Stainless Steel |

| Load Capacity |

100-5000 lbs |

| Natural Frequency |

7Hz-15Hz |

| Model |

GR SERIES |

| Width |

210mm |

| Compression Ratio |

1.2:1 |

| Mounting Thread Size |

M8 |

| Shock Absorption |

Yes |

| Accessories |

Net |

| Isolation Frequency |

10Hz |

| Length |

216mm |

| Working Temperature |

-55°C to +120°C |

| Port |

Xi'an or Specified |

Product Description

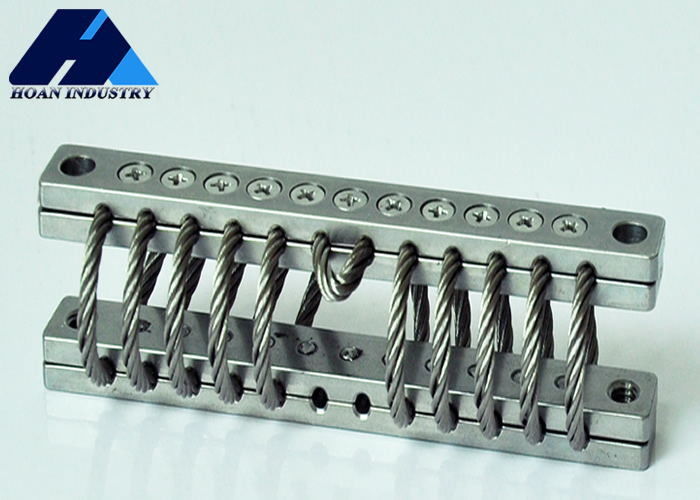

JGX-0320 series wire isolation mounts, also known as wire rope isolators, consist of stainless steel stranded cable threaded through aluminum alloy retaining bars for effective shock and vibration isolation.

With corrosion-resistant, all-metal construction, Xi'an Hoan's wire isolation mounts are environmentally stable, high-performance shock and vibration isolators unaffected by temperature extremes, chemicals, oils, ozone, and abrasives.

The JGX-0320D-20A model features a new design with 10 loops of 3.2mm diameter wire and a maximum static load of 20kg, specifically engineered for noise attenuation in precision instruments.

Constructed from stainless steel, these wire rope isolators offer excellent waterproof, anti-corrosion, and durability performance.

Applications include military vehicles, armored cars, launchers, highway transportation, marine environments, shipbuilding, navy operations, energy systems, photographic equipment, aerial devices, communication apparatus, electronic sensing devices, mobile electronics, cameras, and other demanding working conditions.

Technical Specifications

| No. |

Model |

Max Static Load (kg) |

Max Deflection (mm) |

Kv(vibration) (KNm) |

Ks(Shock) (KNm) |

| 1 |

JGX-0320D-22A |

22 |

9.7 |

154 |

91 |

| 2 |

JGX-0320D-20A |

20 |

11.7 |

124 |

68 |

| 3 |

JGX-0320D-17A |

17 |

13.7 |

95 |

51 |

| 4 |

JGX-0320D-16A |

16 |

16.8 |

78 |

39 |

| 5 |

JGX-0320D-14.5A |

14.5 |

18.8 |

67 |

32 |

| 6 |

JGX-0320D-13.5A |

13.5 |

21.8 |

57 |

25 |

| 7 |

JGX-0320D-12A |

12 |

23.9 |

46 |

21 |

Unique Characteristics

- No creep or ageing

- High internal damping

- Very wide temperature range

- Wide variety of possible fittings

- Rapid and economical prototyping

- Extremely rugged construction and long lifespan

- Excellent combined shock and vibration isolation

- Unaffected by chemical agents, seawater, ozone, UV rays

Material Options

Mounting splint material: Stainless Steel or Aluminum can be selected

Surface Treatment Options for Aluminum Alloy Plywood

White Anodizing: Hardens the aluminum surface while maintaining the natural aluminum color. This is the standard surface treatment for aluminum mounting bars.

Hard Anodizing: Provides significantly greater hardness than white anodizing, resulting in a darker surface color. Recommended for complex or demanding working conditions.

Frequently Asked Questions

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer, not a trading company. We produce our products in our own facilities, ensuring full control over the quality and production process. This allows us to offer competitive pricing and customized solutions directly to our clients.

Q: Can you customize products for us?

A: Yes, we have the capability to customize our products to meet your specific needs. Please contact us with your requirements, and our team will work with you to create a tailored solution.

Q: What is the lead time?

A: Samples typically take 2-5 days. Mass production usually requires 7-20 days, with faster delivery available when we have stock.

Q: Can I get samples before placing an order?

A: Yes, sample orders are accepted.

Q: How is your shipping?

A: Worldwide shipping service is available. Please contact us before ordering as shipping costs may vary.

Q: Do you offer discounts for bulk orders?

A: Yes, we offer discounts for bulk orders. The discount percentage varies depending on order quantity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!